Smart Energy Use Case

Bridgestone

BS Burgos is a large factory, producing the biggest tyres

in the BS portfolio. This means great energy and resources

consumption

• There are several sources or Energy and resources:

• Power

• Compressed Air

• Water

• Steam

• Nitrogen

• Consumption is registered in different meters scattered

along the different buildings of the factory.

• Energy is consumed and paid. Contracts negotiation is

based on volume

Situation before IDboxRT

• BS Burgos is a large factory, producing the biggest tyres

in the BS portfolio. This means great energy and resources

consumption

• There are several sources or Energy and resources:

• Power

• Compressed Air

• Water

• Steam

• Nitrogen

• Consumption is registered in different meters scattered

along the different buildings of the factory.

• Energy is consumed and paid. Contracts negotiation is based on volume.

Problem

• The information about energy consumption is scattered along the factory

• It is not possible to consolidate the information:

• From different meters for the same resource

• From different resources

• IDboxRT consolidates data from different sources:

• Industrial protocols

• SCADAs

• Databases

• Other sources of information.

• Monitors real time data.

• Incorporates analysis tools for data historical base

and machine learning

• Provides consolidated view of the information by

means of synoptics and dashboards.

• Create reports for business decision support.

• Provides information to other company business

support tools.

IDboxRT solution for BS

IDboxRT consolidates data about consumption of

energy and resources.

Information is delivered to Energy Committee in

form of:

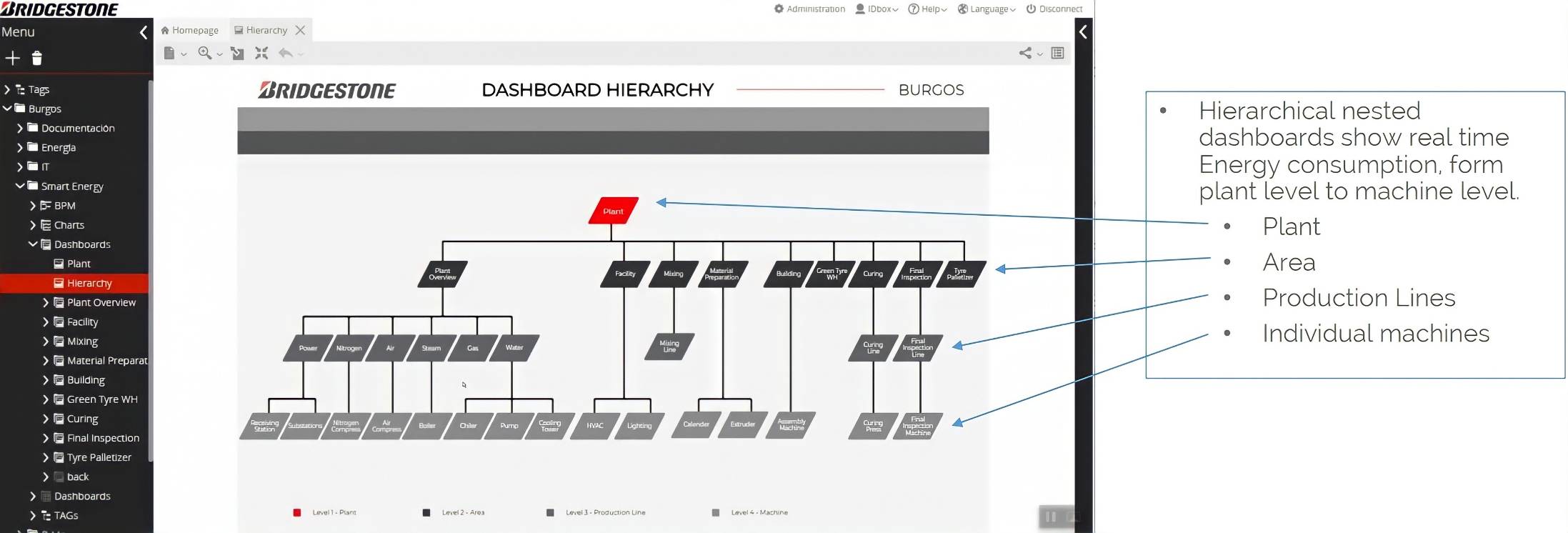

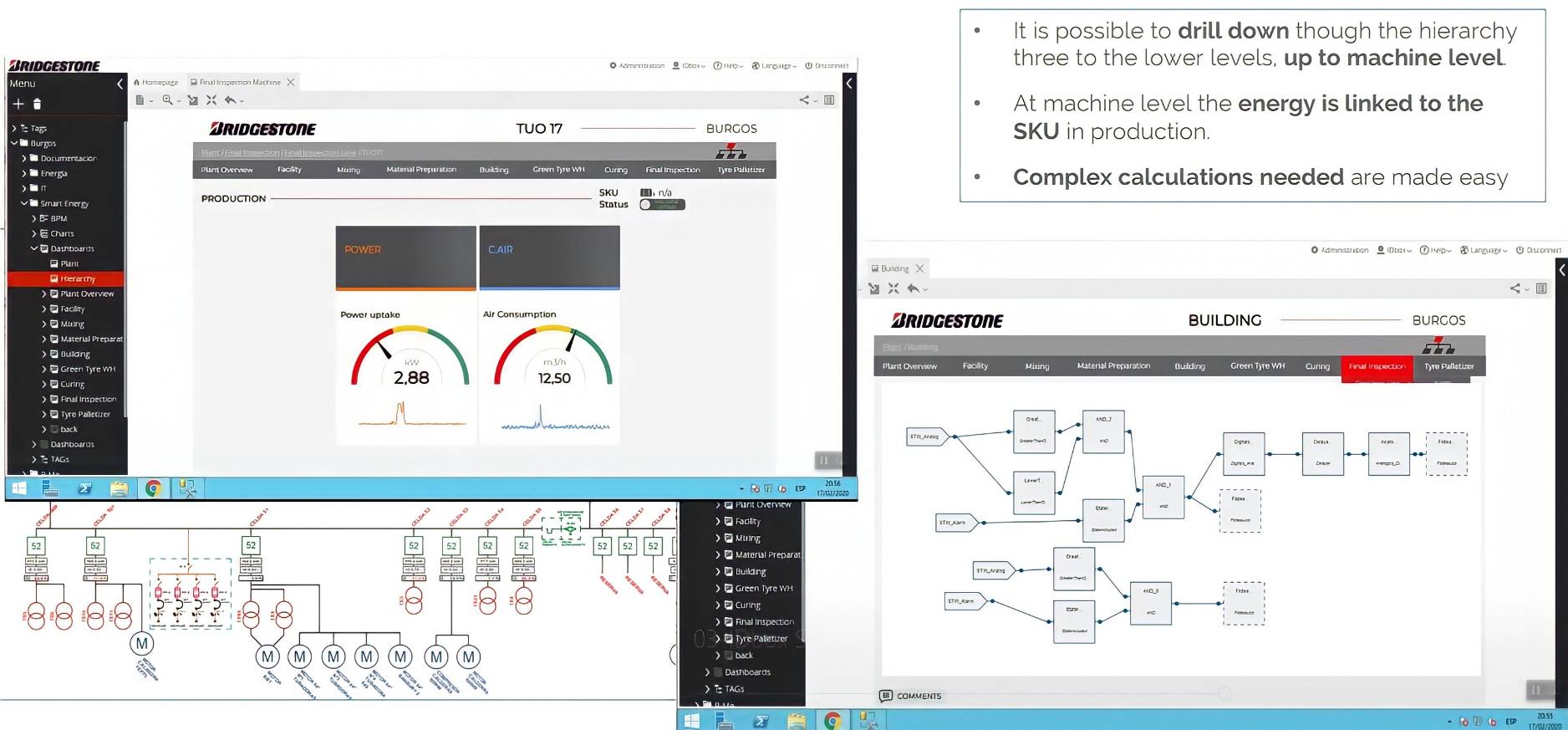

• Hierarchical nested dashboards show real time

Energy consumption, form plant level to

machine level.

• Predefined information analysis

Energy committee now has the possibility to

understand the energy consumption break down.

• How energy is consumed at every level

• How energy is consumed upon the model of

tyre produced.

And provide an unique authorized source of energy

information for the different BS stakeholders.

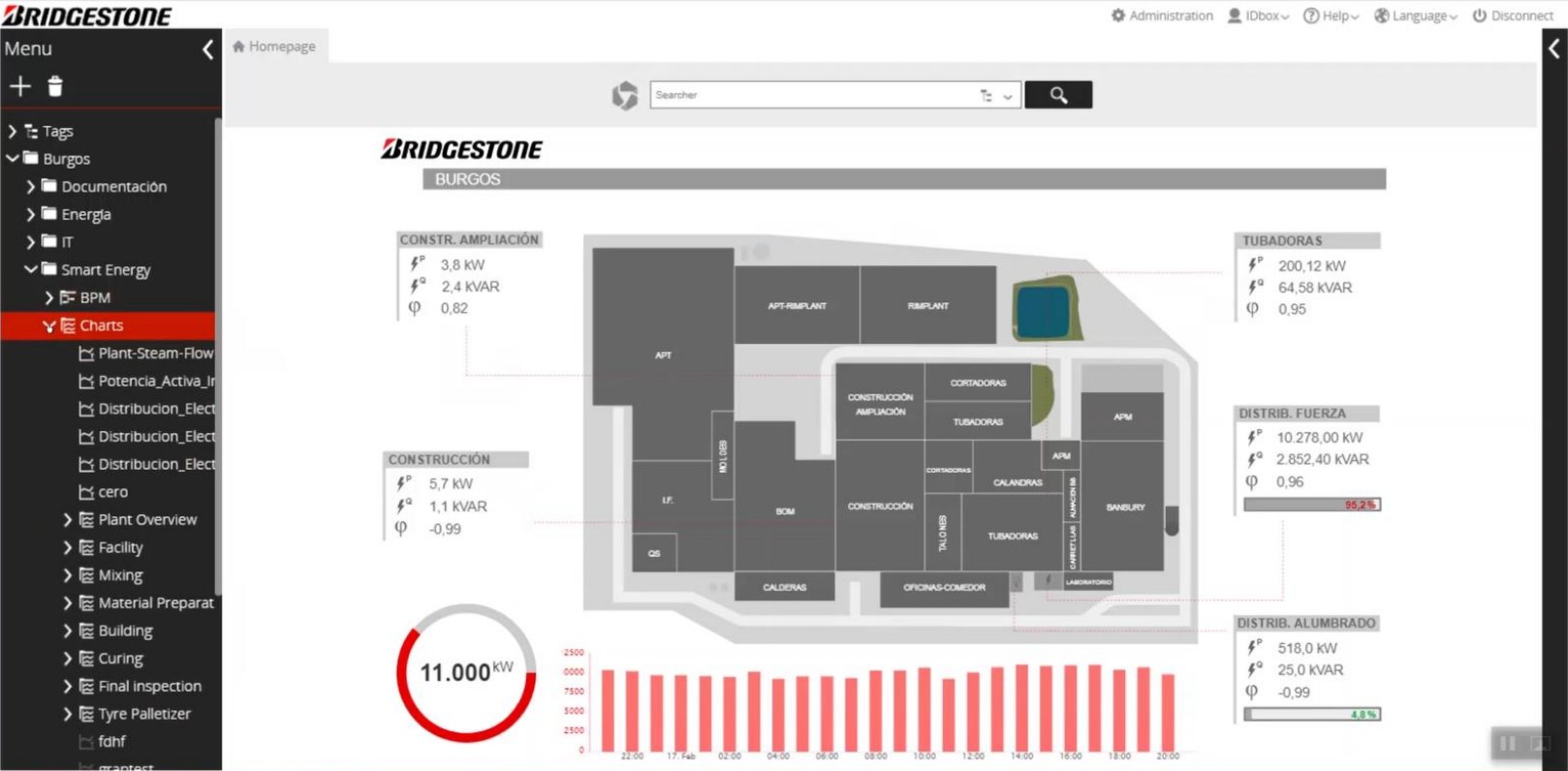

Hierarchical plant representation

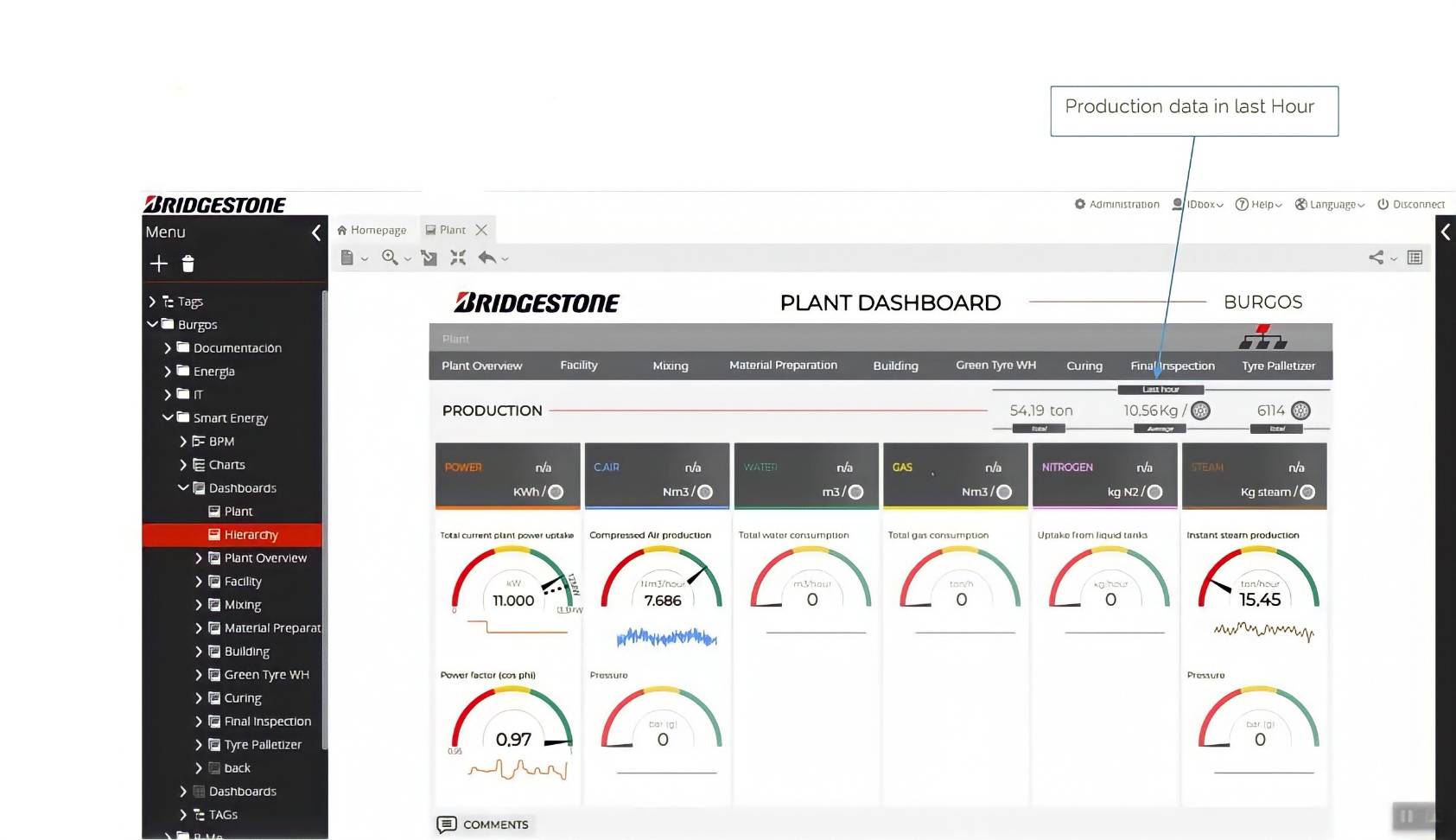

Hierarchy drill-down (Plant view)

Energy committee can easily check, at a glance:

• Consumption of the different energy an resources in the plant, including:

• Real time value (gauge)

• Last ten minutes (graph).

• Production in the last hour:

• Tons of material used.

• Average weight per tyre

• Tyres produced.

Hierarchy drill-down (Other views)

IDboxRT solution in figures

- Reduction of 20% in men working days (mwd)

- related to energy data gathering

- Almost 5% of energy bill savings due to

- contract optimization and production

- optimization

- Return of Investment (ROI) below 4 months